A

Double channels system is used for paper picking and laying, enabling simultaneous two-color stamping as well as sammeld ruck. Flat stamping, 3D stamping and embossing can all be performed with different molds.

B

The machine is equipped with front stop, double side gauge and laser sensor to achieve high-precision positioning of ±0.02mm. It features a large hot stamping area with a maximum size of 720mm*460mm.

C

Fully automatic hot foil stamping is adopted, with pressure driven by servo, reaching approximately 4.2T/cm² and being adjustable. The mismatched design of the closing table and pressure table enables quick and easy plate replacement (within 20 minutes).

D

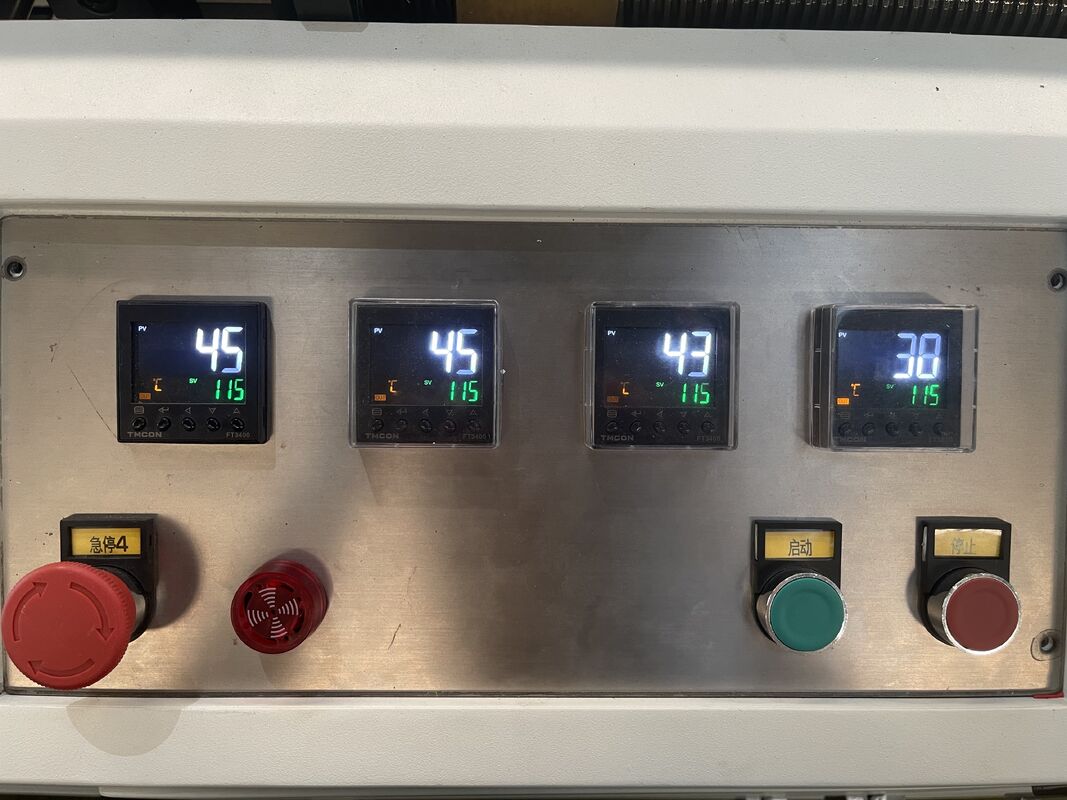

Equipped with four independently adjustable temperature zones, catering to the stamping requirements of various materials (60–150°C).

E

The conveyor belt supports variable-frequency suction adjustment for different paper weights, satisfying the hot stamping needs of various packaging papers. Widely applied to products including gift boxes, wine boxes, cosmetic boxes, clothing boxes, jewelry boxes and more. Minimum applicable paper thickness is 80 grams.

F

Sensors are installed to detect double feeding or no feeding of paper. Upon completion of stamping, paper is automatically collected by the machine.

G

CAM paper feeding is adopted, with a maximum stacking height of 300mm and a production speed of approximately 15–25 pieces per minute.

H

The closing table employs a jack-up, crank and dual-force linkage mechanism.

Specification of Hot Foiling Stamping Machine

| Specification |

| Model:LY-720TJ |

| paper size(L*W) Max: 720*500mm Min: 260*120mm |

| stamping size(L*W) Max: 720*460mm Min: unlimited |

| Prodction rate: 15-25pcs/min |

| stamp working area: 720*460mm |

| paper stacking heigth: 300mm |

| stamping pressure: 4.2T |

| Precision: ±0.02mm |

| the max stamping roll: 2 rolls |

| the max diameter for stamping: 100mm |

| Power supply: 380V |

| Constant power: 13kw |

| Machine size:L3000*W1550*H1000mm |

| Machine weight:4000kg |

| |

| |

Details:

Machine appearance drawing

The conveyor belt implements variable frequency suction adjustment for different grams of paper to meet all kinds of package paper hot stamping needs. And configure sensor to test feed double or no feed paper.

The machine with front stop, double side gauge and laser sensor for a high precision positioning,±0.02mm. Large hot stamping area, 720mm*460mm.

Four temperature zones, all can be adjusted, so that can meet different materials' stamping needs. (60-150 degrees)

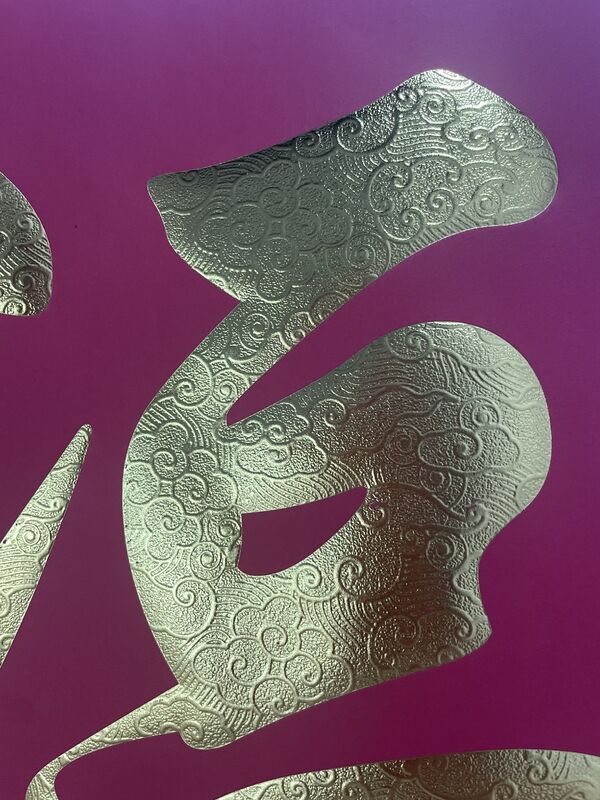

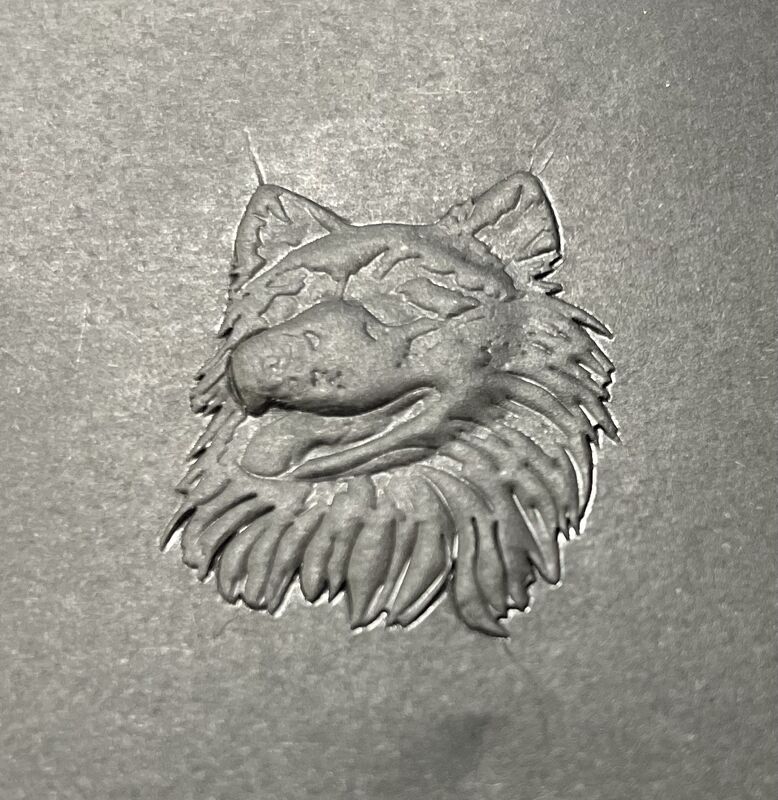

3D hot foiling stamping effect picture

3D embossment effect picture

Flat hot foiling stamping effect picture

Color register

Company Introduction

LiShunyuan was founded in 2001, located in Dongguan city, Guangdong Province Daojiao town Nanya Industrial zone, and has a modern standard workshops of 20000 square meters, after 20 years of development,

the company in domestic has formed a complete sales network and after-sales service system, product sales network and after-sales service system, product sales throughout the whole of China, exported to Europe and the united states,

Southeast Asia, South America, Middle East, Africa and so on more than 40 countries and Regions.

Innovation is the core competitiveness of Lishunyuan. The company owns independent intellectual property products including rigid box series, clamshell box series,

widely used in the production of gift boxes, mobile phone boxes, cosmetic boxes, liquor & wine boxes , and other boutique boxes.

Workshop

Package & Delivery

Quality After-sales Service

1. Before delivery, customer can arrange personnel to train in our company.

2. We will send our engineer to the buyer's factory, but the buyer should bear all the charges, like the air tickets, food,visa and all local charges.

3. We provide 15 days of training service for free of charge.

4. 24 hours service online!

Certificate

Trade Show

FAQ:

1. What about machine warranty?

---- 1 year warranty including free machine parts replacement ( consumables are not included).

2. When the machine breaks down, how do you help us solve the problem

----① We have local service team.

----② 24 hours service online,we will provide you the online support.

3. What machines are used to make rigid boxes?

---- Necessary equipments:Grooving machine, Die Cutter, Printing Machine, Paper feeding and gluing machine, Box corner pasting machine, Box positioning machine, Box wrapping machine, Lining machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!