Servo Motor Automatic Pick And Place Machine 7500 X 2400 X 2000mm

Product Description:

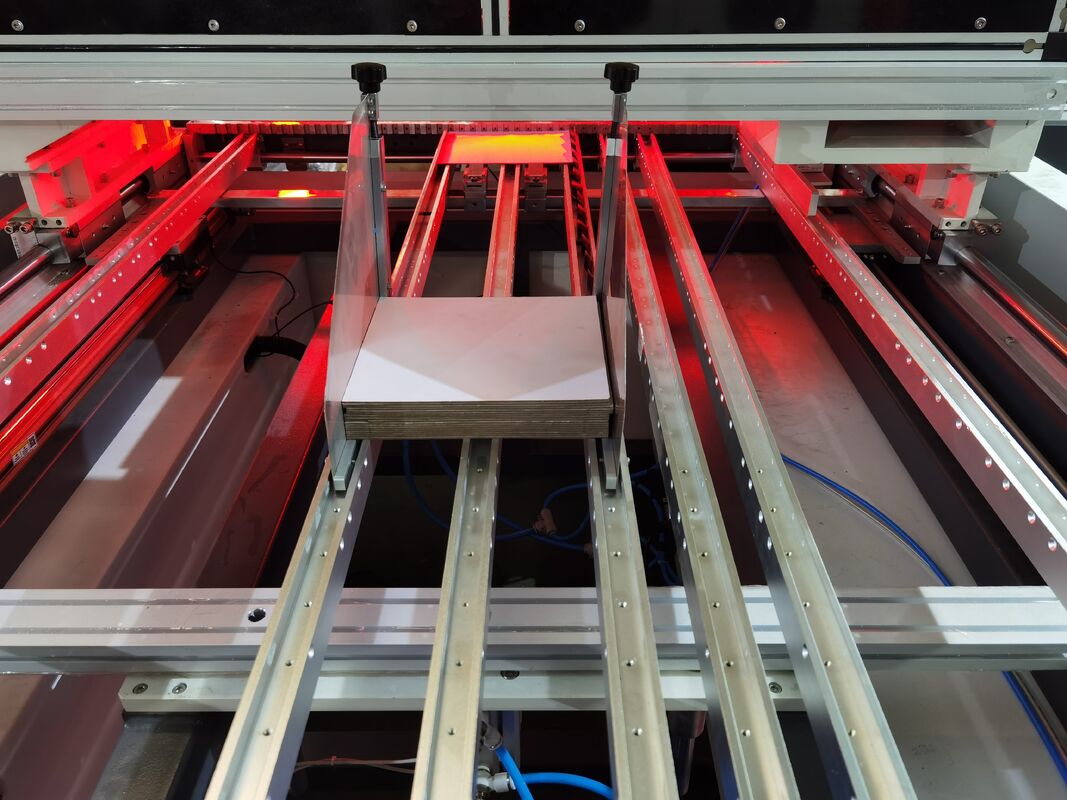

The Automatic Positioning Machine is a state-of-the-art solution designed to enhance efficiency and precision in various industrial applications. This advanced equipment integrates cutting-edge technology to deliver seamless and reliable automation, making it an indispensable asset in modern manufacturing processes. As an Automatic Pick And Place Machine, it excels in automating the handling and positioning of components, significantly reducing manual labor and minimizing errors.

One of the standout features of this Automatic Positioning Machine is its fully automatic operation. The machine is engineered to perform precise pick and place actions without the need for continuous human intervention. This automation not only accelerates production but also ensures consistent accuracy, which is crucial for industries where precision is paramount. By utilizing the Automatic Pick And Place Machine, manufacturers can achieve higher throughput and improved product quality, ultimately leading to increased profitability.

At the heart of this machine lies a sophisticated PLC control system equipped with a user-friendly touchscreen interface. The PLC (Programmable Logic Controller) serves as the brain of the machine, orchestrating all operations with remarkable efficiency and reliability. The touchscreen interface provides operators with an intuitive platform to monitor, adjust, and optimize the machine’s performance in real-time. This combination of PLC and touchscreen technology ensures that the Automatic Positioning Machine is not only easy to operate but also highly adaptable to various production requirements.

In terms of physical dimensions, the Automatic Positioning Machine measures 7500 mm in length, 2400 mm in width, and 2000 mm in height. These dimensions make it a compact yet robust piece of equipment that can be seamlessly integrated into existing production lines without occupying excessive floor space. Despite its relatively modest footprint, the machine’s design maximizes operational efficiency and facilitates easy maintenance, contributing to minimal downtime and sustained productivity.

The core components driving the functionality of this Automatic Pick And Place Machine are the PLC and motor systems. The PLC ensures precise control over every aspect of the machine’s operation, from timing to sequence execution, while the high-performance motors provide the necessary power and speed to execute rapid and accurate pick and place movements. This synergy between control system and mechanical components guarantees smooth and reliable performance, even under demanding production conditions.

Production speed is a critical factor in any automated system, and this Automatic Positioning Machine delivers impressive throughput capabilities. It can handle between 35 to 45 pieces per minute, depending on the specific application and component size. This high-speed operation enables manufacturers to meet tight deadlines and scale up production without compromising on quality. The Automatic Pick And Place Machine’s ability to maintain consistent speed and precision makes it an ideal choice for industries ranging from electronics assembly to packaging and beyond.

In summary, the Automatic Positioning Machine represents a perfect blend of automation, precision, and user-friendly technology. Its automatic operation, powered by a reliable PLC with a touchscreen interface, ensures that production processes are both efficient and easy to control. The machine’s compact dimensions and robust core components, including the PLC and motors, make it a versatile and durable solution suitable for a wide range of industrial applications. With a production speed of 35-45 pieces per minute, this Automatic Pick And Place Machine significantly enhances manufacturing capabilities, reduces labor costs, and improves overall product quality.

For businesses looking to modernize their production lines, investing in this Automatic Pick And Place Machine is a strategic move towards greater automation and operational excellence. It offers a reliable, fast, and precise method for component handling and positioning, ultimately contributing to higher productivity and competitive advantage in the market.

Features:

- Product Name: Automatic Positioning Machine

- Core Components: PLC and Motor

- Positioning Accuracy: ±0.05 mm

- Dimensions: 7500 X 2400 X 2000 mm

- Drive Type: Servo Motor

- High precision Automatic Pick And Place Machine

- Reliable and efficient Automatic Pick And Place Machine

- Advanced technology used in this Automatic Pick And Place Machine

Technical Parameters:

| Production Speed |

35-45 pcs/min |

| Drive Type |

Servo Motor |

| Applicable Industrial |

Manufacturing Plant, Printing Shops |

| Voltage |

380V |

| Key Selling Points |

Automatic |

| Warranty |

1 Year |

| Positioning Accuracy |

±0.05 Mm / ±0.1 Mm |

| Dimensions |

7500 X 2400 X 2000 mm |

| Processing Type |

Box Machine |

Applications:

The Lishunyuan Automatic Positioning Machine, model 485C, is an advanced Automatic Pick And Place Machine designed to meet the rigorous demands of modern manufacturing environments. Originating from China and certified with CE, this machine exemplifies reliability and precision, making it an ideal choice for industries requiring high-speed and accurate positioning solutions. Its compact dimensions of 7500 X 2400 X 2000mm allow it to fit seamlessly into various production lines without occupying excessive floor space.

One of the standout features of this Automatic Pick And Place Machine is its exceptional positioning accuracy, boasting a tolerance of ±0.05 mm to ±0.1 mm. This level of precision is achieved through its core components, including a high-performance PLC and motor system, ensuring consistent and repeatable results. With a production speed of 35-45 pieces per minute, the 485C model is perfectly suited for applications where both speed and accuracy are crucial.

This machine is widely applicable in various scenarios such as electronics assembly, automotive parts manufacturing, pharmaceutical packaging, and food processing industries. In electronics, it efficiently picks and places delicate components onto PCBs with minimal error, enhancing product quality and reducing waste. Automotive manufacturers benefit from its ability to handle heavy-duty parts with consistent precision, streamlining assembly processes. In pharmaceutical and food sectors, the machine ensures hygienic and accurate placement of items, complying with strict industry standards.

The Lishunyuan 485C Automatic Pick And Place Machine is also designed for easy integration and operation within existing production lines. Its delivery time of just 7 working days and supply ability of 30 sets per month make it a practical choice for businesses aiming to upgrade their automation capabilities swiftly. The product is shipped securely using film and plywood crates to ensure safe transit. Customers can negotiate pricing and choose flexible payment terms such as L/C or T/T, with a minimum order quantity of just one set, catering to both small and large-scale operations.

In summary, the Lishunyuan Automatic Pick And Place Machine model 485C is an indispensable solution for industries seeking to enhance production efficiency, accuracy, and automation. Its robust design, coupled with high-speed performance and precise positioning, makes it suitable for a wide range of application occasions and scenarios, from intricate electronics assembly to demanding automotive manufacturing and beyond.

Customization:

The Lishunyuan 485C Automatic Positioning Machine is a high-performance Automatic Pick And Place Machine designed to enhance your production efficiency. Originating from China and certified with CE, this Automatic Pick And Place Machine guarantees quality and reliability for your manufacturing needs.

With a production speed of 35-45 pieces per minute and a servo motor drive type operating at 380V, the 485C model ensures precise and efficient box processing. Our Automatic Pick And Place Machine is backed by a 1-year warranty, providing you with peace of mind and dependable service.

We offer flexible customization services starting from a minimum order quantity of 1 SET. The packaging includes secure film and plywood crates to ensure safe delivery within 7 working days. Payment terms are negotiable, including L/C and T/T options, to suit your business requirements. With a supply ability of 30 sets per month, Lishunyuan is committed to meeting your production demands promptly.

Support and Services:

Our Automatic Positioning Machine is designed to deliver precise and reliable positioning for a variety of industrial applications. For technical support, please ensure that you have the model number and serial number of your machine ready when seeking assistance.

To maintain optimal performance, regular calibration and routine maintenance are recommended. Refer to the user manual for detailed instructions on cleaning, lubrication, and part replacement schedules.

If you experience any issues with the Automatic Positioning Machine, first consult the troubleshooting section of the manual. Common issues such as positioning errors, mechanical jams, or software glitches are addressed with step-by-step solutions.

Our technical support team is available to assist with advanced troubleshooting, software updates, and hardware repairs. We offer comprehensive service plans to extend the lifecycle of your machine and ensure continuous operation.

For spare parts and accessories, please refer to the parts catalog included with your machine or available on our website. Using genuine parts helps maintain the accuracy and durability of your equipment.

We also provide training services to help your staff operate and maintain the Automatic Positioning Machine effectively and safely. Customized training sessions can be arranged to meet your specific operational requirements.

Stay up to date with the latest software releases and product enhancements by registering your product on our customer portal. This ensures you receive timely notifications and access to exclusive resources.

Thank you for choosing our Automatic Positioning Machine. We are committed to supporting your success through quality products and dedicated service.

Packing and Shipping:

Product Packaging:

The Automatic Positioning Machine is carefully packed using high-quality, durable materials to ensure safe transportation. Each unit is securely placed in a custom-fitted foam insert within a sturdy cardboard box to prevent any damage during handling and shipping. All accessories, manuals, and cables are organized and packed separately within the box. The packaging is clearly labeled with product information, handling instructions, and fragile warnings to guarantee proper care throughout the delivery process.

Shipping:

We offer reliable and timely shipping services to deliver the Automatic Positioning Machine to your location. The product is shipped via reputable carriers with tracking options available for your convenience. Depending on your location, multiple shipping methods are available, including standard, expedited, and express delivery. We ensure that all shipments comply with international shipping regulations and include all necessary documentation for smooth customs clearance.

FAQ:

Q1: What is the brand and model number of the Automatic Positioning Machine?

A1: The Automatic Positioning Machine is from the brand Lishunyuan, and the model number is 485C.

Q2: Where is the Automatic Positioning Machine manufactured?

A2: This machine is manufactured in China.

Q3: What certifications does the Automatic Positioning Machine have?

A3: The machine is CE certified, ensuring it meets European safety and quality standards.

Q4: What are the payment terms and delivery time for this product?

A4: Payment can be made via L/C or T/T, and the delivery time is typically 7 work days after order confirmation.

Q5: What is the minimum order quantity and packaging details for the Automatic Positioning Machine?

A5: The minimum order quantity is 1 set. The machine is carefully packaged using film and plywood crates to ensure safe transportation.

Q6: What is the supply ability of the Automatic Positioning Machine?

A6: The supply ability is 30 sets per month, allowing for timely fulfillment of orders.

Q7: Is the price of the Automatic Positioning Machine fixed?

A7: The price is negotiable, depending on order quantity and specific requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!