LY-HB1500CZIntelligent High-Speed Rigid Box Production Line

LY-1500CZ Automatic Rigid Box Machine is the one of the most advanced fully auto box machines by our company. It is suitable to make various types of rigid boxes for mass production, such as mobile phone boxes, gift boxes, cosmetic boxes, watch boxes, slanting boxes etc. more suitable for current packing market, LY-1500CZ adopts PLC and man-machine control, camera tracing system, and can automatically feed cover paper, feed grey board, paste four corners, spot grey board, lift box, wrap box, fold corner edges and form box.

Feeder

1. Feeder control by servo motor

2. Big diameter pneumatic vacuum control valves

3. The rubber pressure roller for the feeding-in paper

4. Double color of conveyor belt , easy for any color of paper

5. The automatic lifting function for feeding stack

6. Feeding stack auto stop when top paper in position Feeder control by servo motor.

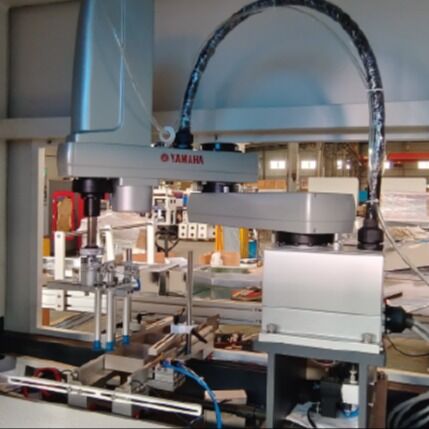

Positioning

1. Japanese Yamaha Robot Arm for spotting the box

2. Camera with Japan Lens in 10 million Pixel tracing system

3. Double Camera with XY Spool for positioning.

Corner pasting

|

1. Mechanical structure,stable and durable.

2. Easy to set up.

3.Tape width in 19mm.

|

Forming Part

|

1. Automatic Setting By servos and setting time in 15mins

2. Within memory functions , max able to save 1000 products.

3. Virtual cam servo driving system. Alarm device for colliding

4. Box Holding in and out , Scratch resistant for the paper

5. No need to change Blade,Brush and pressing plate.

|

Quality After-Sales Service

1 Hour Service

We will reply to your service request call within one hour with solution suggestion.

12 Hours Service

The GM's office will handle customer's complaints directly and reply within 12 hours with solution.

Reach Within 24 Working Hours

The maintenance team will be in place within 24 working hours for customers located within 500km of the service point range.

1 Time/Month

By re-visiting the customers on a monthly basis, customers can rest assured and worriless.

Pre-sale Service

Before delivery, customer can arrange personnel to train in our company. We have teachers of professional electronic engineer and mechanical engineer and we will arrange technical engineers live training of changing different products in the machine at the same time. Inspect the machine comprehensively when training.

Sale Services

When the machine reached your company, we will arrange technical engineers to install and debug, and provide a week of training service for free of charge, then carry out the training services for the production in big batch.

After-sales Service

We will establish completed customer files, record the customer usage at any time, and re-visit to find out usage status and performance of equipment regularly. And also provide professional services of software and hardware updates, functional improvement. We have senior and strong after-sales service team and complete spare parts warehouse to satisfy customers quickly and timely.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!