Positioning For Box Making Machine In The Packaging Machines

LY-485C-PK Fully automatic case making machine, is a combination of visual positioning, four sides covering modules. It's suitable for making all types of book style case, (such as mobile phone boxes, moon cake boxes, tea boxes, cosmetics boxes) hardcover bookcase, notebook covers, desk calendar, folders, etc.

Product features:

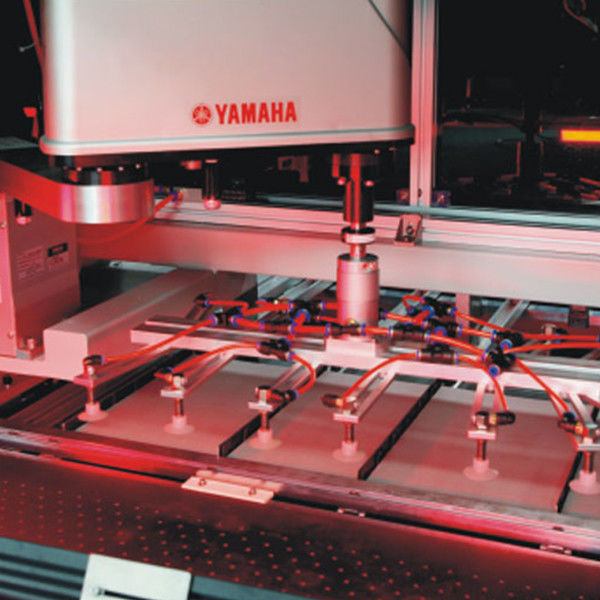

- l Using two industrial cameras with five mega pixels, and YAMAHA robot arm to position, high positioning accuracy(±0.1mm).

- l High production rate, with case making and mounting speed at 20-30pcs/min.Using an independent man-machine control system, transfer machine time is short, fast transfer version.

- l Using independent automatic control system, time for machine adjustment is short, quick to shift mold.

- l Mainframe module can be adjusted to position rigid box, positioning accuracy within±0.1mm, speed 20-30pcs/min, can be optionally matched with corner pasting machine, splicing board box making machine or pneumatic machine and can be extended to produce different kinds of products in future.

Consists of following sections:

1 . Feeder control by servo motor

2. Paper-feed-in overturn function

3. Big diameter pneumatic vacuum control valves

4. The rubber pressure roller for the feeding-in paper

5. Anti-static platform for paper

6. The automatic lifting function for feeding stack

7. Feeding stack auto stop when top paper in position Feeder control by servo motor

Positioning

1 . SCARA (Selective Compliance YAMAHA Robot Arm) for spotting the grey board box

2. Germany Balser camera with Japan Kowa Lens in 10 million Pixel tracing system

3. Double Camera with XY Spool for positioning.

Forming Part & Bubble Pressing

1. Automatic Setting By servos.

2. Double wrapper increase production

3. Virtual cam servo driving system

4. Alarm device for colliding

5. Lift the box by holding the side of the box

6. Scratch resistant for the paper

7. Box-pressing down-side device

Electric Control System

1. Automatic control By servos with stable.

2.Transfer mold fast, quick adjust machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!