High-Positioning-Accuracy Automatic Rigid Box Making Machine

Description

To meet the demand of the market, LISHUNYUAN based on the decades of packaging machine design and manufacture experience, after more than two years independent R&D, developed intelligent automatic rigid box making machine in 2012, greatly solved common faults of the rigid box making machines on current market, like bubble, scratch, loose side, low turn-in depth, uneven gluing, inaccuracy positioning, time-consuming mold change, etc.

Features

1. Intelligent adjusting, quick mold changing. Suitable for produce various model of rigid boxes in one day.

2. Adopt servo optical fiber positioning system, high positioning accuracy (±0.2mm)

3. With memory function, can recall previously produced box parameters to start producing reducing adjustment time.

4. When forming, the robot arm holds the box up; ensure not to scratch the wrapping paper.

5. Can make ear-to-ear and ear-cross-ear folding box, like iPhone boxes etc.

6. Can make some irregular shape boxes, like high-low boxes bevel boxes, trapezoidal boxes, etc.

7. Max turn in depth is high to 100mm.

8. Optional device: Glue viscosity tester, Splicing board box making machine, Automatic bubble pressing machine,

Notched cardboard glue spraying machine.

Parameters

| Specifications: |

| Paper size |

W: 95 - 600mm |

| L: 120 - 880mm |

| Paper thickness |

80-300g/m2 |

| Max. ear cross ear folding size |

120mm |

| Cardboard thickness |

1 - 3mm |

| Finished box size (W*L*H) |

L: 100 - 400mm |

| W: 60 - 400mm |

| H: 15 - 120mm |

| Turn-in paper size |

7 - 110mm |

| Production speed |

1 time folding 20 - 30pcs/min |

| 2 time folding 16 - 25pcs/min |

| 3 time folding 14 - 18pcs/min |

| 4 time folding 12 - 16pcs/min |

| Positioning accuracy |

±0.2mm |

| Power Supply |

380V/50Hz/3phases |

| Constant power |

30KW |

| Air pressure |

25m3, 0.6 - 0.8MPa |

| Glue tank volume |

50KG |

| Machine weight |

6500KG |

| Max. paper stacking height |

300mm |

| Max. cardboard stacking height |

900mm |

| Machine dimension |

L7000 * W4200 * H3400mm |

Sample Boxes

Process Flow

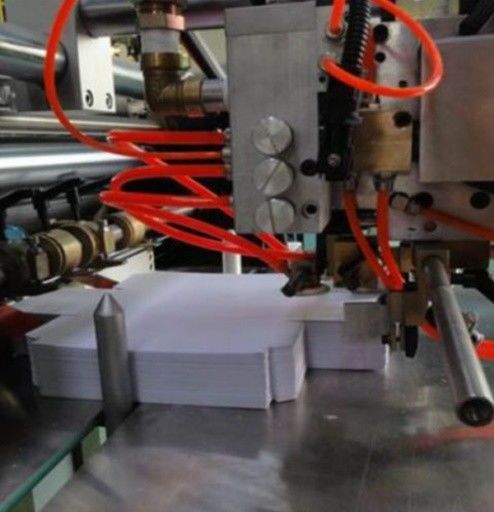

Detailed Images

1. Feeder control by servo motor

2. Big diameter pneumatic vacuum control valves

3. The rubber pressure roller for the feeding-in paper

4. Antistatic platform for paper

5. The automatic lifting function for feeding stack

6. Feeding stack auto stop when top paper in position Feeder control by servo motor

Company Introduction

LiShunyuan was founded in 2001, located in Dongguan city, Guangdong Province Daojiao town Nanya Industrial zone, and has a modern standard workshops of 20000 square meters, after 17 years of development, the company in domestic has formed a complete sales network and after-sales service system, product sales network and after-sales service system, product sales throughout the whole of China, exported to Europe and the united states, Southeast Asia, South America, Middle East, Africa and so on more than 40 countries and Regions.

Innovation is the core competitiveness of Lishunyuan. The company owns independent intellectual property products including rigid box series, clamshell box series,widely used in the production of gift boxes, mobile phone boxes, cosmetic boxes, liquor & wine boxes , and other boutique boxes.

Workshop

Package & Delivery

Certification

Trade Show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!